Ossischkin House

Cupolas, flashing, gutters. Tin coated copper, zinc.

This gem of architecture was buit in 1922, facing the mediterranean, amid sand dunes of the emerging city of Tel Aviv.

After almost century of slow decay, the building was painstakingly restored to its original beauty and additional three storeys of aluminum and glass were added on top of the original structure.

The work was conducted under close guidance of the Conservation Department of Tel Aviv-Jaffa Municipality.

Client: Alberto

Architects: Ogawa Depardon.

Location: —st. Brooklyn, New York.

Bar surfaces. Preweathered Quarz Zinc, 0.8mm VM-Zinc

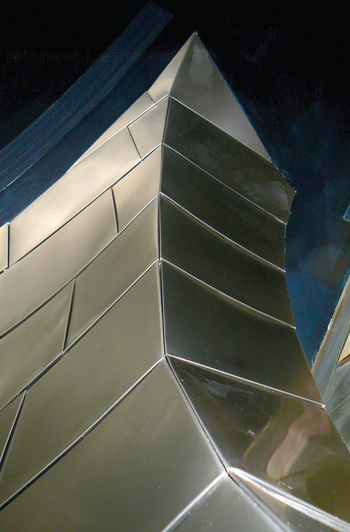

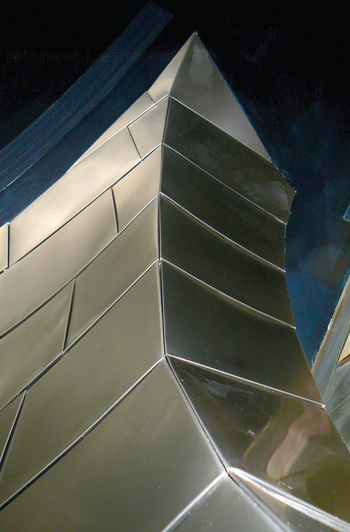

“Heart of The City”, Titanium Wall.

Heart of the City or Rova Lev Ha’ir, is an über-posh real estate project in the heart of Tel Aviv.

I was asked to produce a titanium cladding on number of adjacent curved walls in the lobby of the spa there.

The underlying walls were already erected, but all the other details waited to be solved.

The material and the location in large extent defined for me the details: Identical rectangular panels with flat seams.

The cutting pattern of the panels was modified from the common pattern; all cut edges folded under – so accidental hand brush would not result in an injury. The long seams were receded to soften the stark lines and to hide the sharp metal corners; the vertical seams left as simple 180 deg fold.

The rows of panels were laid in deliberately “random” diagonal, to eliminate the disturbing accidental line-ups with other lines in the lobby.

The vertical seams staggered off-center, at about 1/4 for the same reason.With the start of installation the titanium panels proved to be too stiff to conform to curve. In order to solve this problem, they were re-cut to half their length. Still, in some areas it was not enough, therefore some panels were additionally pre-rolled to conform to the curve.

The work itself was slow, with constant attention to detail. Whatever you do to the metal, it won’t forgive you.

No “Eight Feet Rule” to hide behind.

This set of photos is taken 5 years after the installation. It all looks as on the day one.

Zinc Roof over bay window.

Installed in Autumn 2012.

Client: Arch. Rpberto Petrucelli.

Location: Bayside, Queens, New York.

Material: Graphite Gray Preweathered Zinc, 0.8mm by Rheinzink

My involvement with the project started after the work on the zinc began. The architect, having earlier experience with zinc wasn’t convinced that his contractor really knew how to handle the material. After sharing his concerns with the material distributors in US, he was referred to me.

Zinc, considering its chemical and physical properties, doesn’t look as promising candidate for building envelopes. But it turns out that it is doing its job exceedingly well.

Owner/Architect: Roberto Petrucelli.

Location: Bayside, Queens, New York.

Material: Zinc, preweathered Graphite Gray, 0.8mm, by Rheinzink.

One of my recent projects was a tiny zinc roof over bay-window for the architect Roberto Petrucelli. He was building a super energy efficient home in Queens, New York.

Roberto, having prior experience with zinc, could see that the people brought by his general contractor didn’t have the knowledge to work with this material. His searches for somebody that could do the work lead him to me.

Zinc roofing in USA.

Zinc, judging by its physical and chemical properties, doesn’t look as promising candidate as roofing material.

Despite being known from antiquity, it was never used for roofing, untill 18th century.

Somebody took the pains to to use this cheap by-product of silver smelting as replacement to the much more valuable lead.

He struck it utilizing copper detailing and expertise intristic to lead roofs. While zinc’s workability is similar to copper, its weathering is not; it weathers more like lead.

It was a hit.

Today, zinc is the material of choice for roofing all over North and Western Europe.

Similarly to lead, zinc suffers from pitting corrosion, creep, sensitivity to thermal stress, fatigue and cracking. If not let to expand freely, it cracks extensively around stress points.

Moreover, well weathered zinc is almost impossible to solder, rendering repair attempts futile.

Zinc roofing was introduced to USA at 1816. But its popularity culd be best described as leaps an screeching halts.

if in 1837 there were over 70 zinc roofed buildings in New York alone, by 1840 it was completely out of favor.

The reason for that is lack ofcompetent tradesmen.

Therefore the best investment while installing zinc roof installation is properly trained and well

The secret for a really successful zinc roof, one that stands up to the promise of close to a century of service life, lies in details that are hidden from the eye.

These are: a solid wooden deck, an effective ventilation of the underside of the roof and an intricate system of folded connections that hold the individual zinc panels together.

These folds, besides being water-proof, allow for relative movement between the different zinc parts.

The metal skin is tied down to the wooden deck by an array of metal clips that are welted into these folds.

The water-proofing system resembles much more the functionality of the feathers of a duck than of the shell of a submarine. There is no place for stiff soldered connections and no need for unreliable caulking.

Jaffa Clock Tower.

Erected in 1906, as gift for the Ottoman Sultan Abd al-Hamid II, the ruler of the Ottoman Empire, which included at that time also the Holy Land.

In 1965 the Tower got a make-up, which included new stained glass windows, iron ornaments and plaque commemorating the capture of Jaffa in 1948.

The original zinc cladding of the Tower’s spire, from 1903, was probably redone at that time too, in copper, though some sources put this event later, in the early 80ies.

In 2001 the Clock Tower was renovated again, together with the elongated square it stands on and with the surrounding streets, in an attempt to have it enlisted on UNESCO list of Cultural Heritage sites.

The tower was cleaned thoroughly, the 1965 artwork dismantled, serviced and reattached, new clocks were installed and the copper roof which was in its final stages of deterioration redone.

It was my privilege to participate in this work. It was done with proper KME copper, using methods and sensibilities used by the masters from the “old school”.

However, in my opinion, the aged wooden infrastructure should receive much closer attention than it did. As the project had to conform to schedule and budgetary constrains, it got only new layer of 7/16″ OSB on top of the original decking, and the exposed timber a coat of tar.

Only time will tell when Jaffa Clock Tower roof will get a shiny new metal cladding again, for the fourth time.

The history of the various metal claddings of Jaffa Clock Tower spire makes an interesting study case.

The original zinc work, done by the “old school” trademen seemed to fare pretty well, judging by postcards from early 60-ies. Life span of 65 years (or 80 according to the other sources) is good, comparing to 75 years generally accepted for zinc, considering that the hostilities of 1948 left their mark on the roof and the damages were never addressed properly.

The second reiteration of the Jaffa Clock Tower roof, in copper didn’t survive 36 years (or 20, basing on the other sources). The reason for such poor performance lies in:

Damaged timber, which being left untreated in 1965, caused considerable sagging in the dormers and leaks. In 2001 some timbers were completely rotten away;

Inferior grade of copper, with elevated contents of impurities (such as zinc and iron), which virtually rusted away in splash zones like iron would rust;

Lack of determination and knowledge to do things properly; inferior workmanship.

Copper roofs have life expectancy of 100 to 150 years. The limiting factor is aging of their wooden infrastructure.

There are numerous well documented cases of copper roofs surviving 500-600 years. In these cases the robust timber, made of timber, made of woods much more resistant than the common pine or spruce may last even longer. But for the roofing grade copper 0.7mm to 1.0mm thick, with its wash out rate of over 1/1000mm per year, that is the limit.

Having this in mind, we can see that the first re-roofing, done somewhere between 1965 and early 80-ies did survive 20% of its expected service life, while the “economical” grade copper only 5%!

Making generous assumption that the copper used was half the price of one of prime quality, it still leaves it 10 times more expensive for its intended usage!

Residential home in rural Western Connecticut.

The house is still under construction.

The black hued Anthra Zinc (by VM-zinc) counter-balanced by spans of glass and accented by natural mahogany produces the well balanced exterior envelope of the house.

My task there was to develop the details of the zinc cladding system.

Waterproofing is achieved by utilising traditional connection details, without reliance on “smart” materials.

Mandarin Oriental Rivera Maya, Mexico.

Juan of Diseño Conceptos y Opciones en Arquitectura S.A. called me one day and invited to fly over to Cancun for a few days.

He had there a copper roofing project for the future resort of Mandarin Oriental and his guys in a critical stage encountered technical difficulties.They were not sure how to proceed.

Few days later I got there. I examined the existing plans and the progress of the work. After that we had then a long meeting, during which we discussed the different aspects of the work and possible solutions. At the end of this meeting, Juan proposed to me to manage the project for him. We agreed that I will stay there and manage the project for him for a while. As it turned out, I stayed there till the project’s completion.

My duties there included: revision of architect’s blueprints; redesign of details; management of changes and additions to the original scope of the project; preparation of production drawings; supervision over and participation in production and in installation; coordination of the work of our team with representatives of the main contractor and architects.

[portfolio_slideshow]

Piazza of the The Government Center. Haifa.

My project there consisted of two kinds of copper elements:

One was several copper roofs over small structures scattered around

the central court of the complex;

The second, an array of 12 copper arches erected over the central walk-way.

While the roofs were conventional, double standing seam work,

the arches (thin copper skin applied over tubular space frame) were more of a challenge.

The site, located next to the port and to the the sea beyond it, with several tall buildings in vicinity, held promise of very windy conditions, threatening to pry the copper free of the frames.

The design of the stainless frame, as supplied by the architect, had to be modified to provide adequate rigidity. The girders layout was rearranged and when the first skeleton arrived from the welder’s workshop, it behaved perfectly. It had just enough flexibility for twisting motion along its length. This was necessary for allowing pairing of the arches with the fixing bolts sticking out of the top of the concrete columns. After tightening the bolts, this flexibility disappeared too.

Fastening of the copper to the structure with screws, rivets and glues didn’t seem to work right. So the copper segment’s ends were fixed to the structure by just bending them over flat edges that were welded to the underside of the frames for this purpose.

On a visit six years later I found that the arches aged gracefully.

No loose pieces, no cracks, no sign of wear. Just evenly oxidized copper and green streaks where runoff rainwater trickles over the lime stone.

[portfolio_slideshow]

Corrugated Aluminum – Details Study.

Golad family is in a business of advanced building materials.

One of the new arrivals in their company repertoire – coated corrugated aluminum – was selected as a material for envelope of their new residency, and also serve as a study case.

Corrugated metal is strongly associated with low cost auxiliary structures used in agriculture and industry, therefore one of the aims of the project was re-examine its usage and to devise a new approach, with a set of details that would de-associate the corrugated metal from its current, cheap image.

The system is simple and easy to work with. High degree of reliability is achieved by utilizing solutions taken from traditional metal roofing.