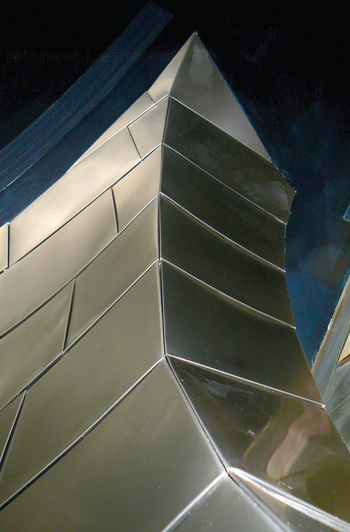

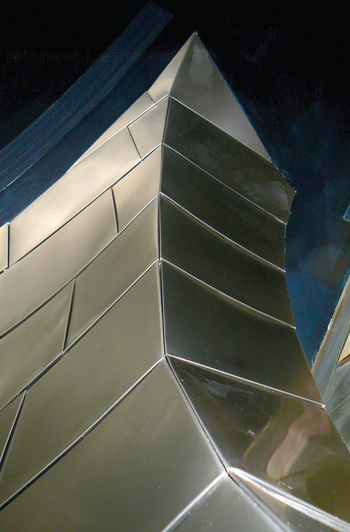

“Heart of The City”, Titanium Wall.

Heart of the City or Rova Lev Ha’ir, is an über-posh real estate project in the heart of Tel Aviv.

I was asked to produce a titanium cladding on number of adjacent curved walls in the lobby of the spa there.

The underlying walls were already erected, but all the other details waited to be solved.

The material and the location in large extent defined for me the details: Identical rectangular panels with flat seams.

The cutting pattern of the panels was modified from the common pattern; all cut edges folded under – so accidental hand brush would not result in an injury. The long seams were receded to soften the stark lines and to hide the sharp metal corners; the vertical seams left as simple 180 deg fold.

The rows of panels were laid in deliberately “random” diagonal, to eliminate the disturbing accidental line-ups with other lines in the lobby.

The vertical seams staggered off-center, at about 1/4 for the same reason.With the start of installation the titanium panels proved to be too stiff to conform to curve. In order to solve this problem, they were re-cut to half their length. Still, in some areas it was not enough, therefore some panels were additionally pre-rolled to conform to the curve.

The work itself was slow, with constant attention to detail. Whatever you do to the metal, it won’t forgive you.

No “Eight Feet Rule” to hide behind.

This set of photos is taken 5 years after the installation. It all looks as on the day one.

Zinc Roof over bay window.

Installed in Autumn 2012.

Client: Arch. Rpberto Petrucelli.

Location: Bayside, Queens, New York.

Material: Graphite Gray Preweathered Zinc, 0.8mm by Rheinzink

My involvement with the project started after the work on the zinc began. The architect, having earlier experience with zinc wasn’t convinced that his contractor really knew how to handle the material. After sharing his concerns with the material distributors in US, he was referred to me.

Zinc, considering its chemical and physical properties, doesn’t look as promising candidate for building envelopes. But it turns out that it is doing its job exceedingly well.

Owner/Architect: Roberto Petrucelli.

Location: Bayside, Queens, New York.

Material: Zinc, preweathered Graphite Gray, 0.8mm, by Rheinzink.

One of my recent projects was a tiny zinc roof over bay-window for the architect Roberto Petrucelli. He was building a super energy efficient home in Queens, New York.

Roberto, having prior experience with zinc, could see that the people brought by his general contractor didn’t have the knowledge to work with this material. His searches for somebody that could do the work lead him to me.

Zinc roofing in USA.

Zinc, judging by its physical and chemical properties, doesn’t look as promising candidate as roofing material.

Despite being known from antiquity, it was never used for roofing, untill 18th century.

Somebody took the pains to to use this cheap by-product of silver smelting as replacement to the much more valuable lead.

He struck it utilizing copper detailing and expertise intristic to lead roofs. While zinc’s workability is similar to copper, its weathering is not; it weathers more like lead.

It was a hit.

Today, zinc is the material of choice for roofing all over North and Western Europe.

Similarly to lead, zinc suffers from pitting corrosion, creep, sensitivity to thermal stress, fatigue and cracking. If not let to expand freely, it cracks extensively around stress points.

Moreover, well weathered zinc is almost impossible to solder, rendering repair attempts futile.

Zinc roofing was introduced to USA at 1816. But its popularity culd be best described as leaps an screeching halts.

if in 1837 there were over 70 zinc roofed buildings in New York alone, by 1840 it was completely out of favor.

The reason for that is lack ofcompetent tradesmen.

Therefore the best investment while installing zinc roof installation is properly trained and well

The secret for a really successful zinc roof, one that stands up to the promise of close to a century of service life, lies in details that are hidden from the eye.

These are: a solid wooden deck, an effective ventilation of the underside of the roof and an intricate system of folded connections that hold the individual zinc panels together.

These folds, besides being water-proof, allow for relative movement between the different zinc parts.

The metal skin is tied down to the wooden deck by an array of metal clips that are welted into these folds.

The water-proofing system resembles much more the functionality of the feathers of a duck than of the shell of a submarine. There is no place for stiff soldered connections and no need for unreliable caulking.

Residential home in rural Western Connecticut.

The house is still under construction.

The black hued Anthra Zinc (by VM-zinc) counter-balanced by spans of glass and accented by natural mahogany produces the well balanced exterior envelope of the house.

My task there was to develop the details of the zinc cladding system.

Waterproofing is achieved by utilising traditional connection details, without reliance on “smart” materials.